X-ray computed tomography (CT) as a non-destructive technique for imaging the inner structure of objects has undergone a major technical and instrumentation development at the turn of the millennium. This allowed its significant use and expansion in industry. Nowadays, CT is an indispensable tool for trouble-shooting, design, improvement and quality check of the products. The actual trends of industrial CT development are in robotization for inspection automation, resolution improvement up to sub-micron level or implementation of high energy sources (linear accelerators) for inspection of large and massive objects.

New platform of industrial

computed tomography (CT)

Nondestructive testing of

large scale and heavy samples

small component only / whole assembly

larger samples

LINACTON is high energy CT focused on industry

Common expertise

- Dimensional inspection

- Porosity evaluation

- Position verification of assembly components

- OK/NOK comparison

- Reverse engineering

- 3D printing optimization

Industrial fields

Aviation

Automotive

Battery industry

Casting

3D printing

Nuclear energy

Astronautics

High Energy CT

Check out demo videos about already existing High Energy CT systems.

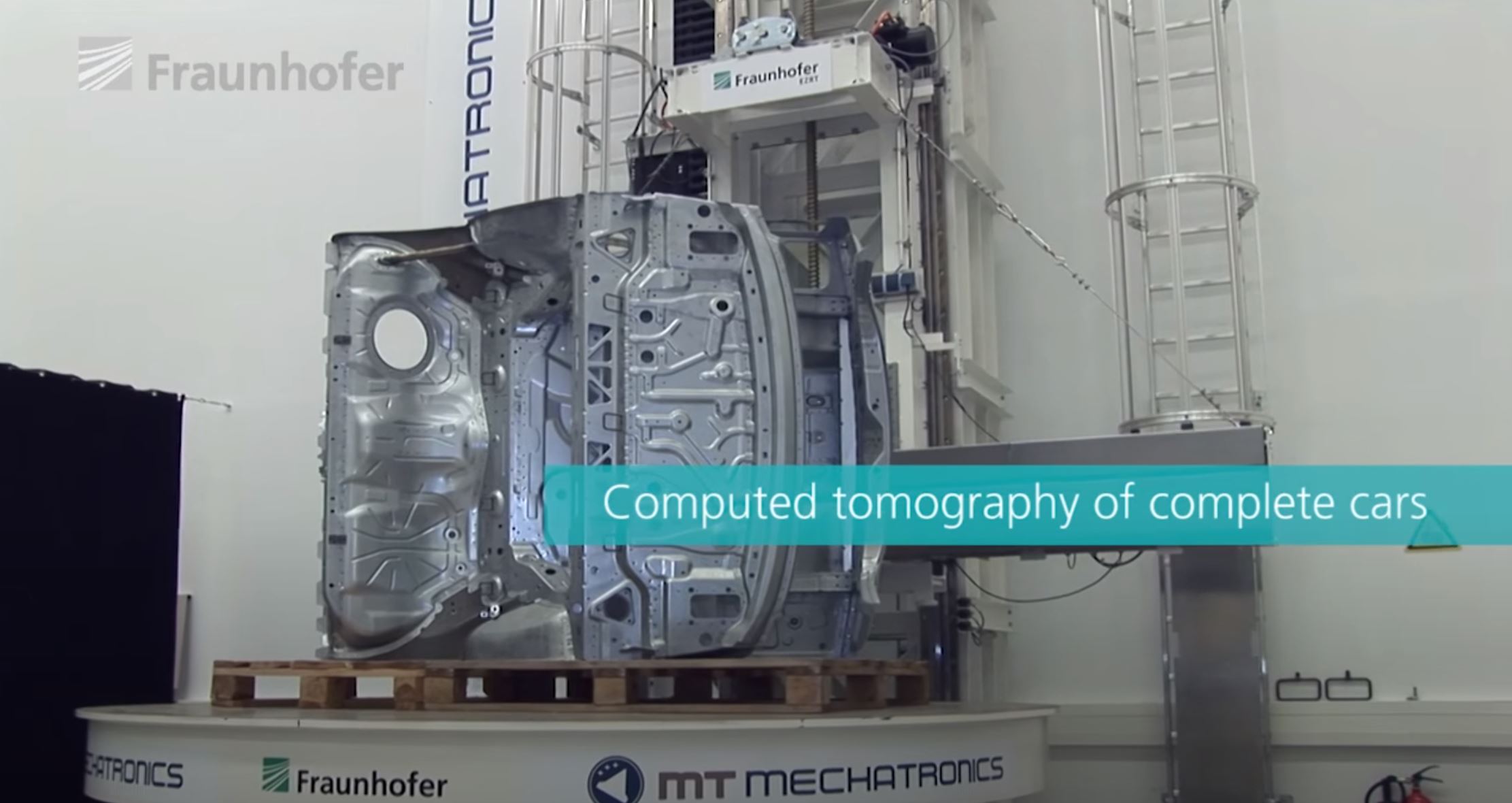

XXL CT

Fraunhofer IIS/EZRT

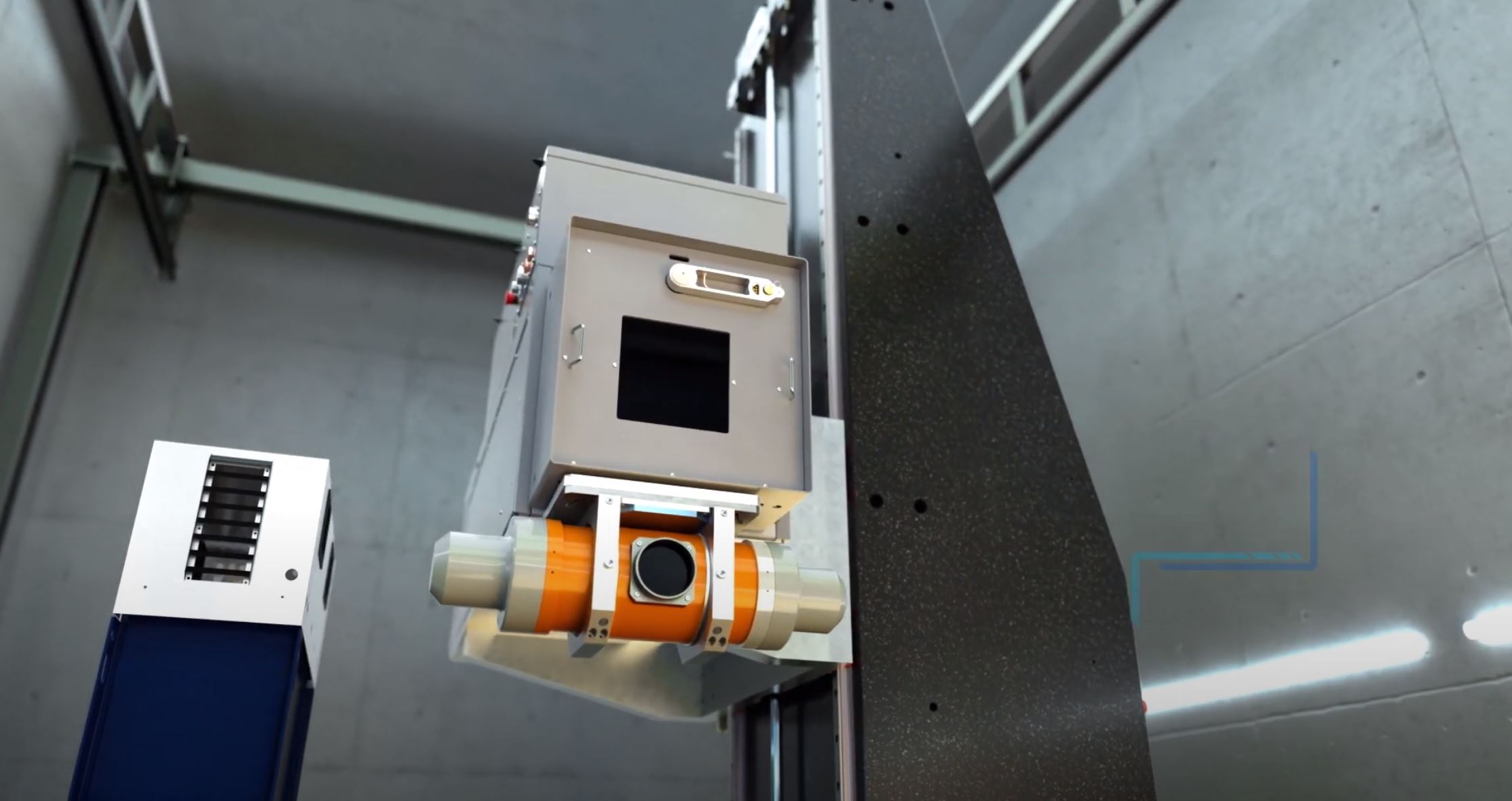

Phoenix Power|scan HE

Waygate Technologies

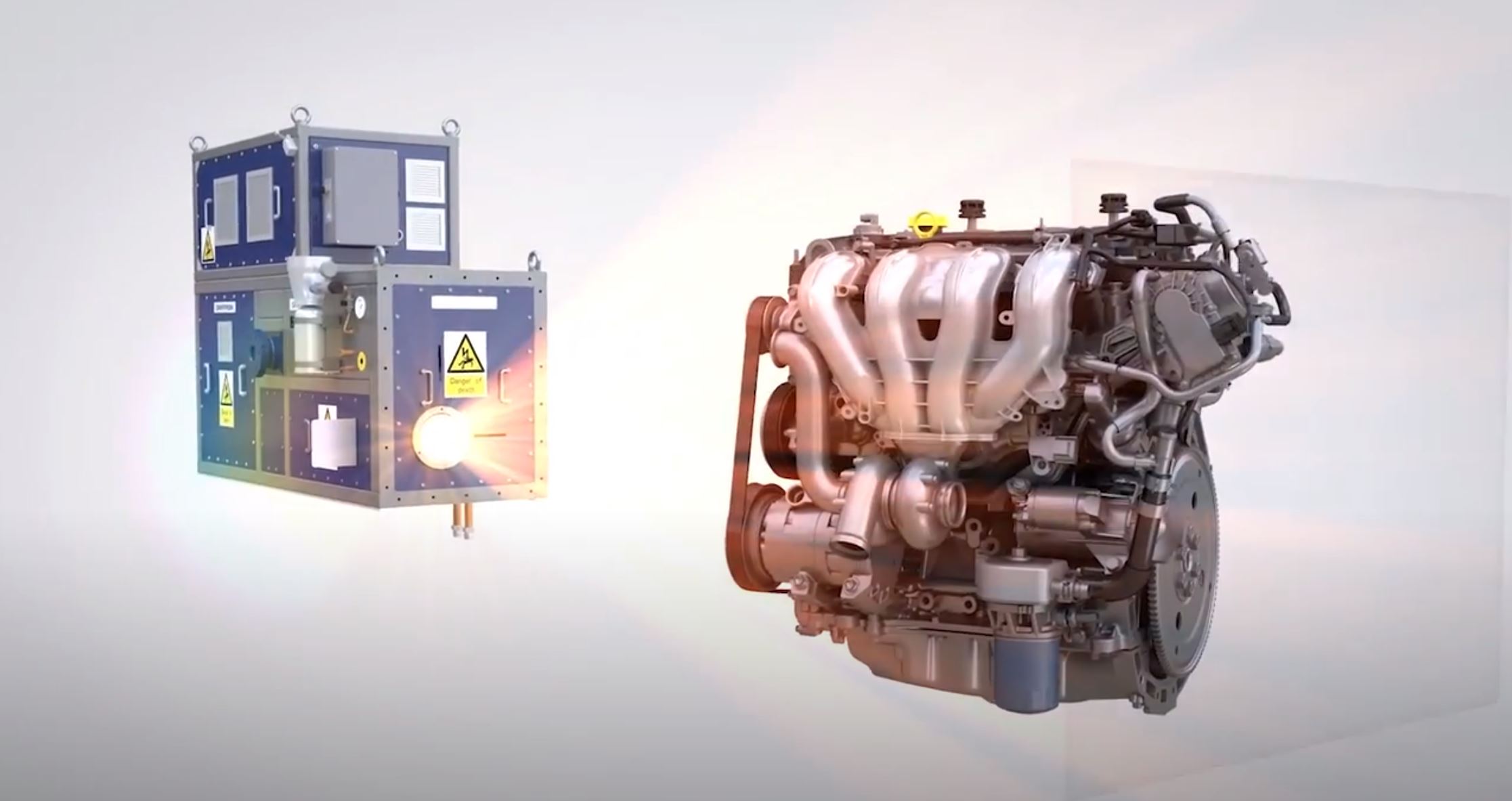

Oriatron

PMB-ALCEN

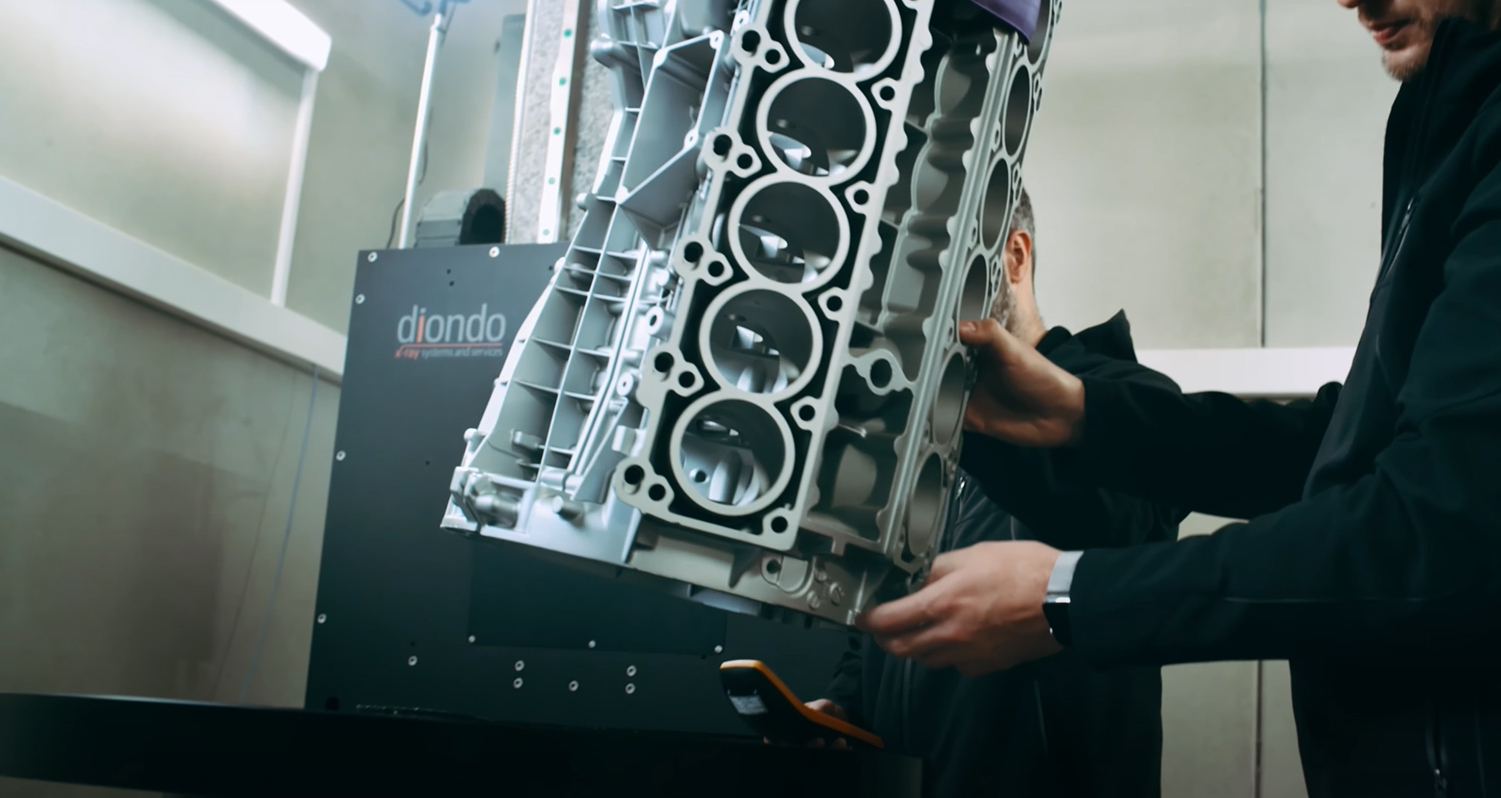

diondo d7

diondo GmbH

See LINACTON in action

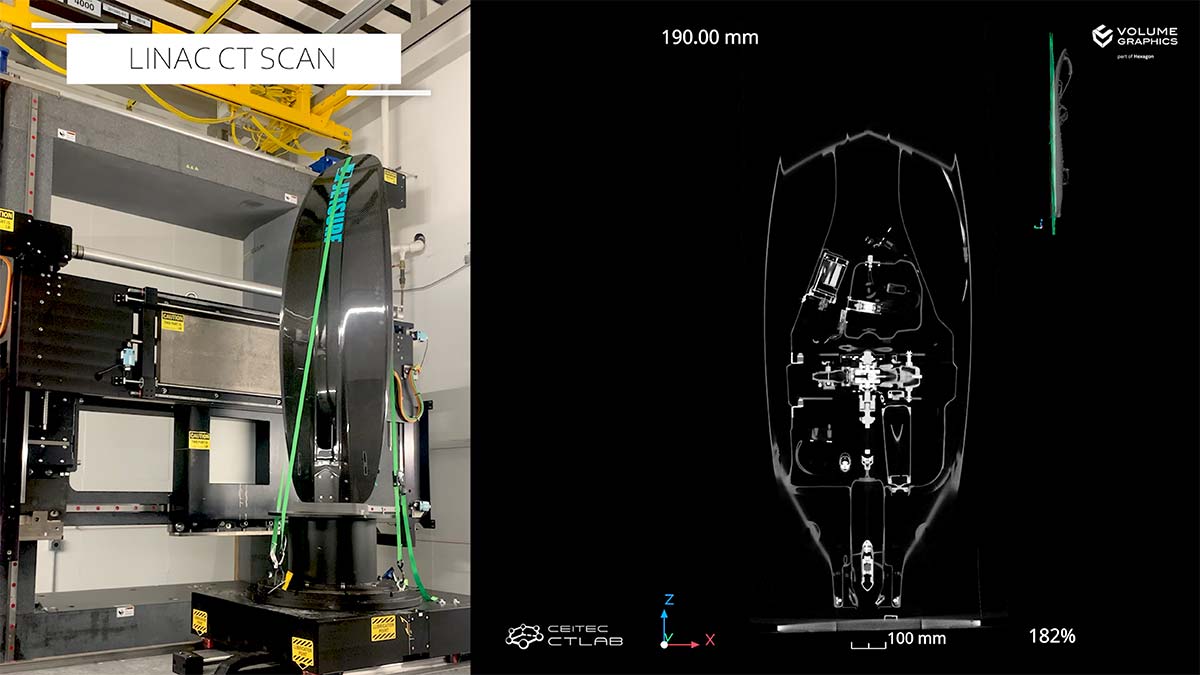

JETSURF® utilisation

Linacton in cooperation with Cincinnati centre 2022

Product: Jetsurf, Motorized Surfboard

Dimensions: 1800×600×150 mm, Weight: 34 kg

- Dimensional measurement

- Right positions of parts

- Glue joints quality

- Rubber sealings

- Complete 3D reconstruction

Output characteristics:

12k transversal cross-sections

150 μm voxel resolution

300GB of original data

LOCATION

Brno / Czech Republic

LINACTON is going to introduce new platform of industrial non-destructive testing with emphasis on professional expertise accessibility, close cooperation with Research Centres and flexible operational regime driven by industrial needs.

PROJECT SCHEDULE

1) INITIATION

$ 99

Per Month- Survey of industrial requests

- Screening of technologies

- Establishment of an experts team

2) PLANNING

$ 99

Per Month- Designing facilities

- Technological partner

- Project foundation

3) CONSTRUCTION

$ 99

Per Month- Buildings

- Concrete bunker

- Store-house

- Loading place

4) INSTALLATION

$ 99

Per Month- CT system installation

- Radiation safety

- Initial testing

- Monitoring

5) USE

$ 99

Per Month- Open access workflow

- Professional expertises

- Big data handling

ABOUT US

Based on long-term cooperation with industry, the CT system manufacturers themselves and the gained experience, the research centre Central European Institute of Technology (CEITEC BUT) and LINACTON s.r.o. are joining together to expand their portfolio with a high-energy X-ray computed tomography. For this purpose, a project called LINACTON is being created, the mission of which is to build a new centre with this technology and make it available for general industrial use. This technology is going to help to improve scientific, engineering and technical knowledge in line with current industry trends such as automation (Industry 4.0) and electrification (e-mobility).

LINACTON s.r.o. is a start-up company of CEITEC BUT. CEITEC BUT works with CT application and development for more than 10 years. Working together with selected global producers of CT instrumentation, it managed to establish several intercooperating laboratories. These laboratories are equipped with complex and complementary state of the art devices, covering a wide range of tomographic analysis. Besides fundamental research in different fields, the activities focus on close cooperation with industry, for which these laboratories provide a high-quality level of digital X-ray radiographic and tomographic expertise.

Contact us

Assoc. Prof. Zdeněk Dufek, Ph.D.

e-mail: dufek@linacton.com

LINACTON s.r.o.

ICO 04670515

Šmídkova 3089/5B, Žabovřesky, 616 00 Brno